97556 Silicone Softener (Soft & Especially suitable for chemical fiber)

Features & Benefits

- Stable in hard water. High shear resistance.

- Imparts fabrics soft, plump and exquisite hand feeling.

- Low yellowing and low shade changing.

- High flexibility. Suitable for various kinds of processes and equipment.

- Safe and stable for using.

Typical Properties

| Appearance: | Light yellow emulsion |

| Ionicity: | Weak cationic |

| pH value: | 6.0~7.0 (1% aqueous solution) |

| Solubility: | Soluble in water |

| Application: | Synthetic fibers, as polyester, nylon and acrylic fibers, etc. |

Package

120kg plastic barrel, IBC tank & customized package available for selection

TIPS:

Importance of chemical finishing

Chemical finishing has always been an important component of textile processing, but in recent years the trend to ‘high tech’ products has increased the interest and use of chemical finishes. As the use of high performance textiles has grown, the need for chemical finishes to provide the fabric properties required in these special applications has grown accordingly.

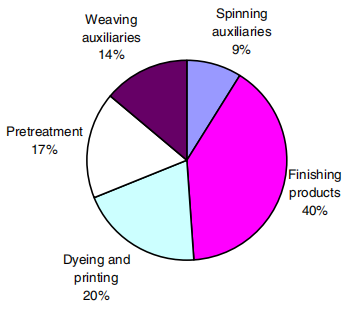

The amount of textile chemical auxiliaries sold and used globally in one year is estimated to be about one-tenth of the world’s fiber production. With fiber production currently at 60 million tonnes, about 6 million tonnes of chemical auxiliaries are consumed. The percentage of market share of textile auxiliaries is shown in below figure. About 40 % of textile auxiliaries are used in finishing, the largest percentage usage of all textile chemicals, followed by dyeing and printing auxiliaries and pretreatment chemicals. Softeners are clearly the most important individual product group. In terms of value, the repellent group is the leader with the highest ratio of cost per amount. This reflects the relatively high cost of the fluorochemical subgroup of repellents.